DRYING SHRINKAGE CRACKING

Attention to adequate provision of bay joints in the screed should considerably reduce the occurrence of drying shrinkage cracks and as far as possible joints in bonded screeds should coincide with joints in the slab, to avoid screed cracking caused by opening of joints in concrete base. See the FeRFA Guide to Specification and Application of Screeds (2.7.1 below) for further information.

FERFA GUIDANCE NOTE No. 15

The following is an extract from the recently issued FeRFA Guide to Specification and Application of Screeds, co-authored by Dr Malcolm Bailey of Radlett Consultants and Ronacrete Limited, with relevant passages highlighted. Copies of the guide are available on request from technical@ronacrete.co.uk or may be downloaded from the FeRFA website http://www.ferfa.org.uk/pdf/FeRFAPublications/TGN15GuidetoScreedsAugust2017-RIBAApproved.pdf

2.7.1 Bay sizes

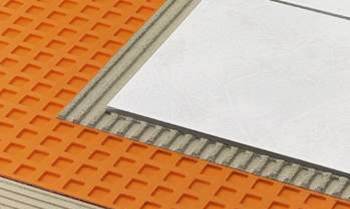

Bonded and unbonded levelling screeds are normally laid in strips some 3 m to 4 m in width. This is to facilitate the use of screeding bars down either side which are used to ensure the correct thickness of screed/surface level. Alternate bays are laid, the bars removed and the infill strip thickness/ surface level is then based on the finished strips either side. Stress relief joints are usually formed every 5 m – 6 m down each strip. Such joints are either formed by cutting through with a trowel or saw-cutting the hardened screed. When choosing to saw cut a screed, the contractor should consider how soon after laying the screed should be cut; stress relief cracks may be formed in fast drying or high strength screeds at a very early stage in the curing process.

The setting out of such bays will depend on several factors. In a bonded screed the joints should follow closely the joints in the concrete base since it is inevitable that these will open and cause a crack in the screed. Similarly, sealant filled expansion/movement joints in the structure should never be screeded over.

In a floating screed designed to receive rigid floorings, bay sizes are normally limited to 40 sq m and positioning of joints will depend on the layout of the heating pipework system if underfloor heating is the reason for using a floating screed.

If ceramic tiling is to be laid as the final floor finish, bay joints in the screed may also need to be carefully set out to coincide with the bay joints in the tiling system.

Long thin strips such as corridors are prone to cracking and should be provided with stress relief joints at intervals, particularly as the screed tends to become restrained at doorways and junctions.

Cementitious (e.g. granolithic) and polymer modified wearing surfaces should be considered in the same way as bonded levelling screeds and joints should coincide with those in the underlying concrete slab.

2.7.2 Cracking

Cracking is caused by either the external forces applied to the screed exceeding the relatively weak tensile strength of the screed or the internal forces within the screed exceeding its tensile strength.

External forces can be applied by the building itself or its major structural components. Hence general movement of the building, e.g. flexing of suspended floors, foundation settlement, thermal expansion and contraction, can exert significant tensile forces on the screed which it does not have the tensile strength to resist. The most common external force is between adjacent ground-supported concrete slabs which are shrinking away from each other in the long drying out period. A screed which is bonded to both slabs and is continuous over the joint between them will inevitably crack.

Internal forces are caused due to the screed itself trying to shrink due to loss of its moisture content. In theory as a floating or unbonded screed dries and shrinks, the edges of the screed will move evenly inwards towards the centre of the area. Unfortunately in practice this may not happen either because the drying and thus the shrinkage is uneven throughout the area of screed, or because the screed becomes restrained at one or more places.

Restraint of the screed, thus preventing it shrinking evenly can be caused by a number of factors. Internal columns in the building, re-entrant corners, manholes, service ducts typically can cause restraint. However, the most common cause is the weight of the screed itself and the friction that is generated thereby on whatever is supporting it. This is why it is important that the concrete slab surface in an unbonded screed is as smooth as possible. It should be clearly understood that reinforcement in the screed will not prevent cracking. It only limits the crack width. The crack will be initiated long before the reinforcement can have any effect.