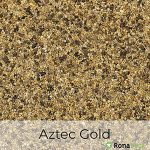

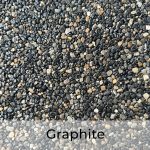

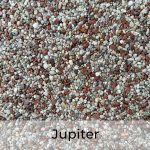

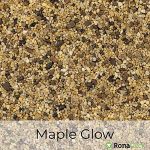

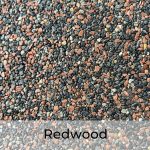

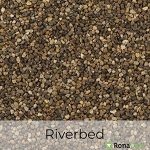

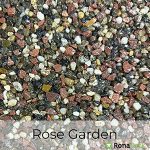

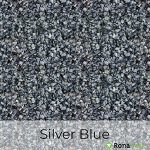

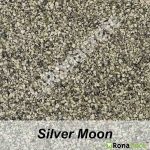

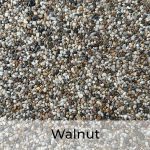

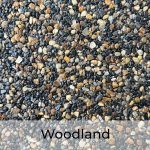

RonaDeck Resin Bound Surfacing Samples

We understand that it can be a difficult decision when it comes to choosing the colour of the finished resin bound surfacing. It can be even more difficult when you can only choose from pictures. For that reason we are able to send out a selection of cured samples so that you can have a closer look at the colours and finishes available.

All you need to do is select up to 4 samples from the selection below and fill out all the required details and we will send them out for you.

All RonaDeck Resin Bound Surfacing aggregate blends have been slip tested in accordance with BS 8204:2008+A1:2010 Appendix B. All aggregate blends have achieved low risk of slip in dry conditions. All but one aggregate blend achieved low risk of slip in wet conditions. Slip Resistance Values can be found on the technical data sheet.

Natural aggregates may contain small amounts of iron which can produce rust staining when exposed to air and water; standard RonaDeck Resin Bound Surfacing blends contain aggregates selected for infrequency of incidence of staining but iron may be present in any natural aggregate. The presence of iron cannot be identified before use and Ronacrete Ltd cannot accept responsibility for any loss or damage suffered as a result of staining.